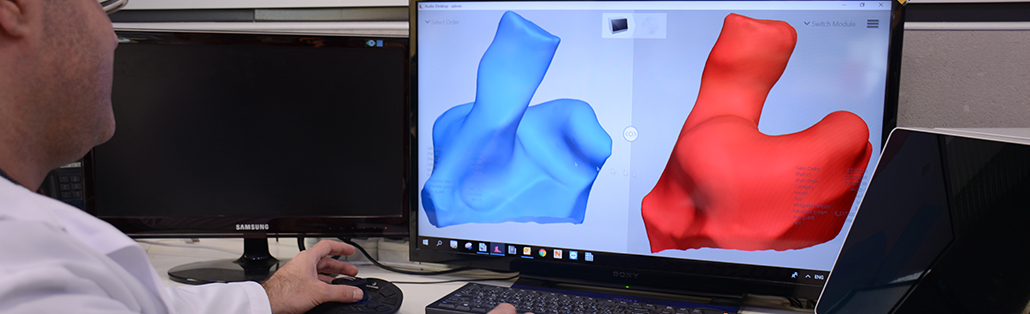

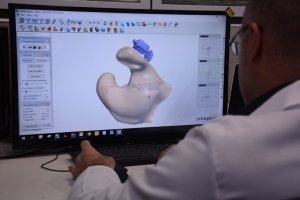

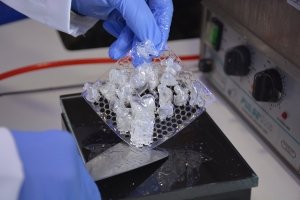

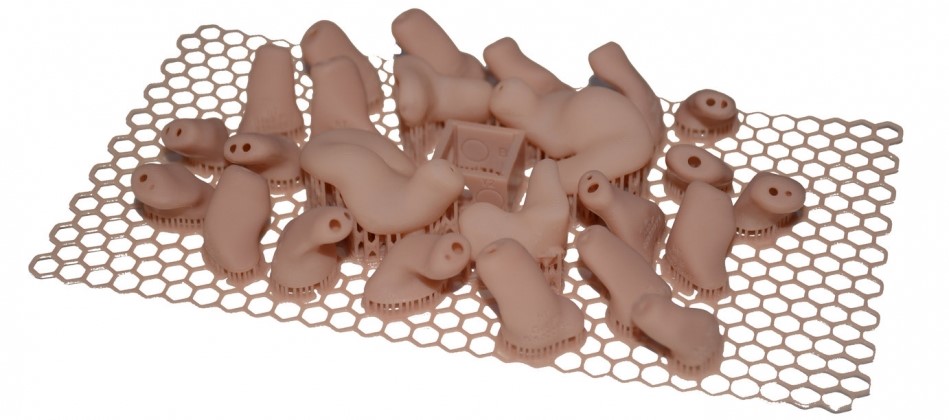

The digitized 3D printing process has shortened the hearing aid manufacturing process to three main steps: Scanning the ear to create an impression; modeling the hearing aid shell through specific software; and printing the hearing aid device layer-by-layer, fitting them with the necessary electronics.

Once a patient gets their ear shape scanned and modelled, all 3D scans and associated data are saved in our database. This is particularly convenient whenever a patient needs a reproduction of their hearing aid or a copy of their ear impression scans.